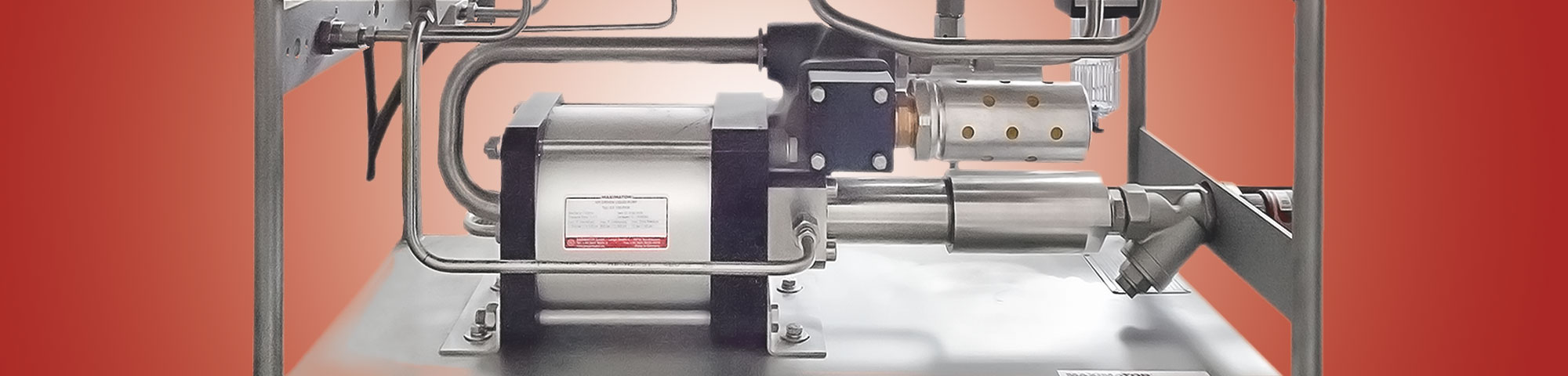

"This pump is able to generate

a test pressure of 1,000 bars.”

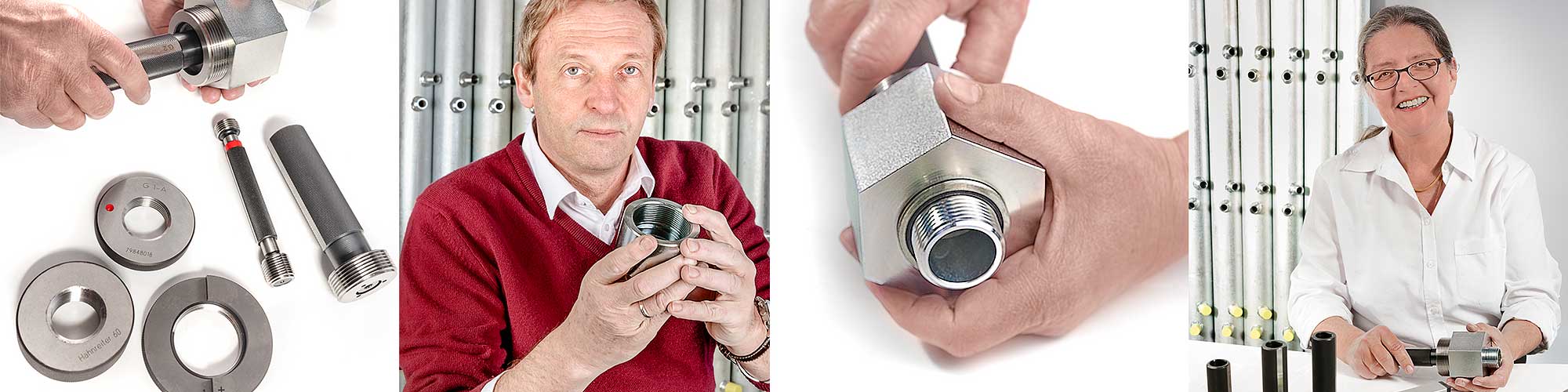

We set the bar very high for quality management

füsser.HDT, represented by Bernd Füsser and Gaby Füsser, coordinates a network of specialists. In addition to project execution, the range of technological services consists of process development and production engineering consultancy within the framework of bilateral partnerships. In this context, füsser.HDT acts as a service provider and performs customer-specific development tasks. With its ever-increasing wealth of know-how, füsser.HDT analyses high-pressure projects and develops innovative solutions that are tailored to meet individual requirements.

"Our partners provide production facilities and state-of-the-art technology.”

füsser.HDT is, thus, able to produce individual, high-precision, and complex turning and milling work pieces. It goes without saying that the welding companies have been certified according to the European Pressure Equipment Directive (PED). We are one of the few providers that can also carry out internal galvanization.

The demands placed on high-pressure supply have grown with regard to safety, handling, flexibility, and durability. Of course, a good price-performance ratio and long-term delivery guarantees are also required. The fact that füsser.HDT meets all of these requirements is evidenced by references from renowned customers who have had faith in our quality for a long time. füsser.HDT guarantees production safety, high profitability, and the assurance of being technically up to date.

Dr. rer. nat. Bernd Füsser und Dr. rer. nat. Gaby Füsser during quality control